Whether it’s a halted assembly line or an unexpected machine failure, unplanned disruptions have long plagued industries. Enter digital twins: virtual replicas of physical assets that are transforming how companies approach their maintenance strategies. With the rise of Industry 4.0, predictive maintenance powered by digital twins is no longer a luxury but a necessity.

By simulating machinery behavior and collecting real-time data, digital twins enable engineers and operators to forecast equipment failures before they occur. These insights drastically reduce downtime, extend the life of critical assets, and optimize performance across the board. When paired with software for industrial quality checks, these predictive models empower manufacturers to not only detect early signs of wear but also maintain strict quality control standards.

What Exactly Are Digital Twins?

A digital twin is more than just a 3D model of a machine. It is a living, breathing simulation powered by live data. Sensors attached to industrial equipment feed the twin with performance data, environmental conditions, and operational statistics. These twins update in real-time, providing users with an exact virtual representation of the machine’s current state.

What sets digital twins apart is their ability to predict future states. Through machine learning algorithms and historical data patterns, these systems can forecast when a component is likely to fail, allowing for maintenance to be scheduled just in time, not too early, and never too late.

Predictive Maintenance: Efficiency Meets Innovation

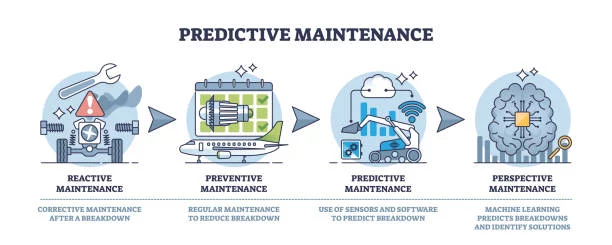

Traditional maintenance methods can be categorized into two types: reactive and preventive. Reactive maintenance addresses breakdowns after they occur, while preventive maintenance involves regular checkups and part replacements, regardless of whether a breakdown has occurred. Predictive maintenance, on the other hand, offers a smarter alternative.

By continuously monitoring equipment through digital twins, predictive maintenance identifies anomalies and degradation before they cause operational issues. This shift leads to lower maintenance costs, a reduced risk of failure, and a more efficient overall production process.

In sectors like automotive, aerospace, and heavy machinery, this approach is game-changing. Factories using predictive maintenance powered by digital twins report significant gains in uptime, reduced operational costs, and enhanced safety measures.

Quality Assurance Gets a Digital Upgrade

Ensuring product consistency and excellence is at the heart of any industrial process. That’s where inspection software plays a crucial role. By integrating digital twins with quality systems, manufacturers can trace how changes in machinery behavior affect product output.

For instance, a slight temperature change in a molding machine could alter product specifications. With a digital twin in place, these deviations are detected in real-time, and adjustments are made before defective items reach the end of the production line. The integration of software for industrial quality checks into this loop ensures that quality standards are not just met but anticipated and maintained with precision.

Challenges to Adoption

Despite its benefits, implementing digital twins and predictive maintenance comes with challenges. High initial investment, data integration complexity, and the need for skilled personnel can slow down adoption. However, as software for industrial quality checks becomes more user-friendly and cloud-based, the barriers are gradually lowering.

Companies that strategically invest in training and infrastructure are finding themselves ahead of the curve, leveraging predictive insights not just to fix problems but to prevent them entirely.

Final Thoughts

As industries strive for zero downtime and flawless production, the marriage of digital twins and predictive maintenance is proving to be an essential alliance. This fusion creates a self-correcting system that not only monitors but also actively enhances industrial performance.

With the added layer of quality inspection software, manufacturers gain complete visibility and control over both their processes and their products. Together, these technologies point toward a smarter, safer, and more sustainable future for industry.

In short, while the path to digital twin adoption may require careful planning, the payoff in efficiency, reliability, and product quality makes the journey well worth it.

Lexy Summer is a talented writer with a deep passion for the art of language and storytelling. With a background in editing and content creation, Lexy has honed her skills in crafting clear, engaging, and grammatically flawless writing.