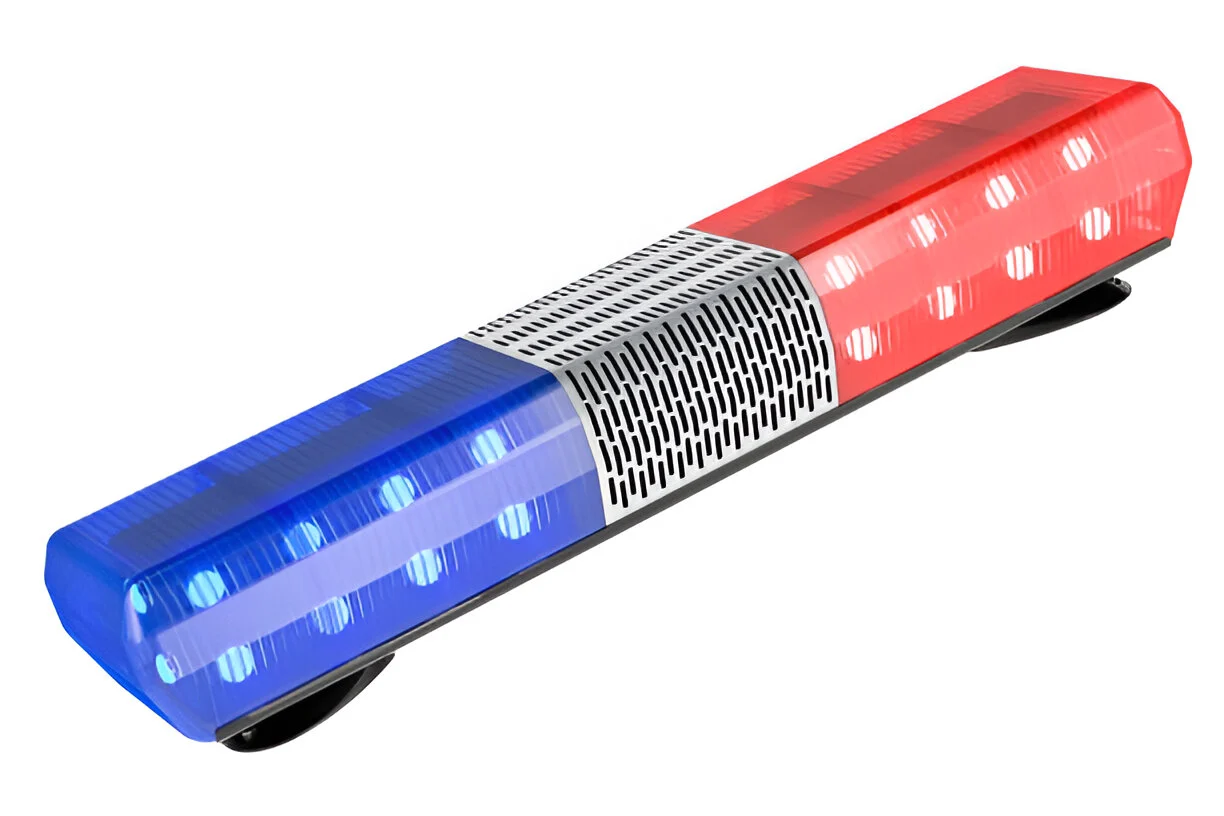

For first responders and emergency vehicle operators, a properly functioning light bar isn’t just about equipment maintenance – it’s about safety and reliability when lives are on the line. So, how do I maintain and clean my emergency light bar to ensure longevity?

Regular maintenance involves monthly cleaning with a mild soap solution, checking all mounting hardware, and inspecting wiring connections for wear or damage. Clean the lens covers gently with a microfiber cloth to prevent scratches.

While this basic maintenance routine covers the essentials, there’s much more to know about protecting your investment and ensuring optimal performance in various weather conditions and environments. Understanding specific cleaning techniques for different types of light bars and how to address common problems can significantly extend the life of your equipment.

What Are The Different Cleaning Methods For Various Light Bar Materials?

LED light bars with polycarbonate lenses require special care to prevent damage. Use only non-abrasive, ammonia-free cleaners, as harsh chemicals can cause clouding and deterioration. For aluminum housings, use a gentle automotive soap and avoid pressure washers, which can force water into seals.

Older halogen light bars with glass lenses can handle slightly stronger cleaning solutions, but still require gentle handling to preserve gaskets and seals. When cleaning any light bar component, always finish by thoroughly drying all surfaces to prevent water spots and potential corrosion issues that could compromise both appearance and functionality.

How Often Should I Inspect And Service My Emergency Light Bar?

Professional inspection should occur every six months, but monthly visual checks are essential. Look for signs of water intrusion, loose connections, or dimming LEDs. During winter months, increase inspection frequency to ensure salt and road chemicals aren’t causing corrosion.

Keep a maintenance log to track patterns and predict potential issues before they become critical failures. This documentation becomes particularly valuable when training new personnel or when transferring vehicles between departments, ensuring consistent maintenance practices regardless of who operates the vehicle.

What Are The Warning Signs That My Light Bar Needs Immediate Attention?

Watch for flickering lights, unusual noise during operation, or visible moisture inside lens covers. If mounting brackets show any rust or the light bar feels loose, address these issues immediately. Pay attention to color changes in LED outputs – if blues appear greenish or reds look pink, this indicates potential LED failure.

Any electrical burning smell or irregular power draw should trigger immediate professional inspection to prevent system failure during critical operations. Remember that emergency situations are the worst possible moments for equipment failure, so treating these warning signs with appropriate urgency can prevent dangerous situations and potentially save lives when your lights need to function perfectly.

How Can I Protect My Light Bar From Environmental Damage?

Extreme weather conditions can significantly impact light bar performance and longevity. Apply a UV-resistant coating annually to prevent sun damage and yellowing of lens covers. In coastal areas, use a marine-grade protectant to guard against salt air corrosion. During winter, remove ice and snow accumulation carefully to prevent stress on mounting points.

Consider installing protective covers when the vehicle is parked for extended periods, especially in areas with heavy bird activity or tree sap exposure. These preventative measures may seem time-consuming, but they significantly extend the operational life of your equipment and maintain optimal performance characteristics when emergency response demands peak functionality.

What Should Be Included In An Emergency Light Bar Maintenance Kit?

Every emergency vehicle should carry a basic maintenance kit specifically for light bar care. Essential items include microfiber cloths, approved cleaning solution, dielectric grease for electrical connections, spare fuses, and a small multimeter for electrical testing. Keep silicon-based lubricant on hand for gasket maintenance, and include spare mounting hardware matched to your specific light bar model.

A basic tool kit with screwdrivers and wrenches sized for your unit’s hardware should also be readily available. Store these items in a waterproof container and keep an inventory list to ensure supplies are replenished when used. Having this dedicated maintenance kit accessible means you can address minor issues immediately rather than allowing them to develop into more serious problems.

When the time comes to replace your light bar or upgrade to newer technology, Shop LED light bars at Ultra Bright Lightz for high-quality options designed specifically for emergency vehicles. In business since 2006, Ultra Bright Lightz has established itself as a trusted supplier of emergency vehicle lighting equipment worldwide. They offer an extensive selection of LED warning lights, light bars, sirens, and controllers from industry-leading brands like Feniex and Whelen, as well as their own cost-effective U-Lite and ilumex product lines.

Conclusion

Start by creating a detailed maintenance schedule for your light bar today – mark your calendar with monthly cleaning dates, six-month professional inspections, and annual protective coating applications. Once you have this schedule in place, you’ll be better positioned to catch potential issues early and ensure your emergency light bar remains reliable when you need it most.

Lexy Summer is a talented writer with a deep passion for the art of language and storytelling. With a background in editing and content creation, Lexy has honed her skills in crafting clear, engaging, and grammatically flawless writing.