How Electricians Collaborate to Build Smarter, Safer, and More Efficient Systems

As technology drives industries toward smarter, more connected operations, the demand for custom automation is rising across sectors like manufacturing, HVAC, healthcare, and commercial facilities. At the heart of these intelligent systems is the electrical control panel—the central hub that orchestrates equipment, power distribution, and process automation.

But behind every high-functioning control system is a team of experts—and one of the most critical players in that team is the electrician. In this post, we’ll dive into the vital role electricians play in the design, fabrication, and implementation of custom electrical control panels, and why their expertise is essential in turning complex requirements into real-world solutions.

What Is a Custom Electrical Control Panel?

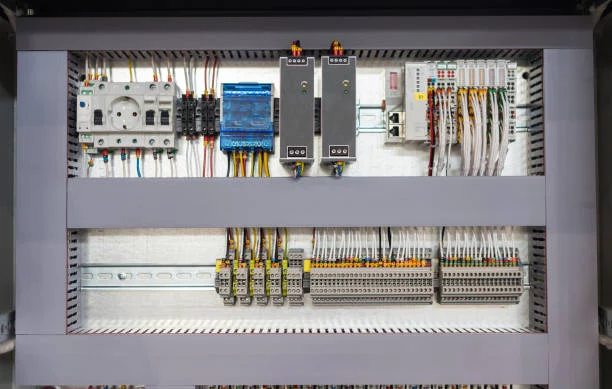

An electrical control panel is a centralized unit that houses electrical components used to monitor and control mechanical processes. While off-the-shelf panels serve standard functions, custom control panels are designed for specific operational needs—whether it’s managing a multi-zone HVAC system, running a manufacturing production line, or integrating renewable energy inputs.

Custom panels vary widely in design and complexity, but they typically include components such as:

- Circuit breakers and fuses

- Relays and contactors

- PLCs (Programmable Logic Controllers)

- Motor starters and variable frequency drives

- Touchscreen interfaces and monitoring systems

The Electrician’s Role: More Than Just Wiring

Electricians are often perceived as the ones who “just install wires,” but in the world of custom automation, their role is far more dynamic and technical. They work closely with engineers, system integrators, and facility managers from the planning phase to final commissioning.

1. Translating Schematics Into Reality

Engineers provide the designs and control logic, but Idaho Falls electricians are the ones who make them work. They interpret wiring diagrams, layout schematics, and control blueprints to bring the panel to life.

- Precise Component Installation: Electricians ensure that every terminal, breaker, and relay is mounted and wired correctly.

- Code Compliance: They ensure the panel adheres to local and national electrical codes (such as NEC or UL standards).

- Troubleshooting Expertise: If a system doesn’t perform as intended, electricians are often the first to pinpoint wiring or configuration issues.

2. Collaborating with Facility Owners

No one knows a facility’s operational needs better than the people running it. Skilled electricians work directly with business owners, facilities managers, and operators to ensure that the custom control panel addresses real-world usage and can adapt to future growth.

Questions electricians might ask during the consultation phase include:

- What types of loads will the panel control?

- Are there plans to scale or automate more processes later?

- What level of monitoring or remote access is required?

This input helps guide decisions on panel size, component selection, and system flexibility.

Specialized Applications: One Size Doesn’t Fit All

Custom electrical control panels are critical in industries where precision, efficiency, and safety are non-negotiable.

HVAC Automation

Electricians help design panels that integrate with building automation systems (BAS), allowing dynamic control of heating, ventilation, and cooling systems based on occupancy, temperature, and energy usage.

Manufacturing & Industrial Automation

From conveyor belts to robotic arms, electricians wire and configure control panels that manage machinery operation, safety interlocks, and performance monitoring.

Energy Management

Panels designed for solar systems, battery storage, or demand-response systems require electricians skilled in renewable integration, grounding strategies, and load balancing.

Healthcare and Labs

Control panels in medical environments often support life-sustaining systems, lab equipment, or climate-controlled environments. Electricians must ensure these systems are fail-safe, compliant, and easily maintainable.

Safety, Reliability, and Scalability

One of the most important reasons to involve a licensed electrician in custom panel projects is safety. Improper wiring, undervalued components, or overlooked grounding can lead to equipment failure—or worse, electrical fires and injuries. Electricians bring real-world knowledge that complements theoretical design, ensuring that every panel is safe to operate and maintain.

They also future-proof installations by:

- Designing panels with room for expansion

- Using modular components for flexibility

- Labeling systems clearly for ease of service and upgrades

Electricians Bring Custom Automation to Life

While engineers may map out the vision, it’s the electrician who makes the system work. Whether it’s wiring complex sequences, ensuring compliance, or working directly with facility owners to adapt to changing needs, their role in creating a custom electrical control panel is indispensable.

In a world increasingly driven by automation, don’t underestimate the electrician’s contribution. If you’re planning a custom panel for your facility, bring them into the conversation early. Their expertise can mean the difference between a system that simply works—and one that performs flawlessly for years to come.

Lexy Summer is a talented writer with a deep passion for the art of language and storytelling. With a background in editing and content creation, Lexy has honed her skills in crafting clear, engaging, and grammatically flawless writing.